|

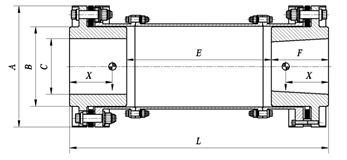

联轴器型号 |

功率/转速 (Kw/rpm) |

公称扭矩 (KNm) |

峰值扭矩 (KNm) |

特大许用转速 (r/min) |

A (mm) |

B (mm) |

C(mm)max |

E(mm) |

F (mm) |

L(mm) |

|

TBR6115 |

0.072 |

0.68 |

2.4 |

32000 |

115 |

62 |

40 |

160 |

45 |

250 |

|

TBR6135 |

0.16 |

1.52 |

3.3 |

28000 |

135 |

82 |

55 |

170 |

60 |

290 |

|

TBR6152 |

0.22 |

2.1 |

6.1 |

25000 |

152 |

98 |

65 |

190 |

70 |

330 |

|

TBR6175 |

0.39 |

3.7 |

10.8 |

23000 |

175 |

105 |

75 |

210 |

80 |

370 |

|

TBR6196 |

0.49 |

4.6 |

12.4 |

21000 |

196 |

115 |

80 |

230 |

85 |

400 |

|

TBR6210 |

0.54 |

5.15 |

14.2 |

20000 |

210 |

130 |

90 |

230 |

95 |

420 |

|

TBR6231 |

0.86 |

8.21 |

24.1 |

18000 |

231 |

150 |

105 |

250 |

110 |

470 |

|

TBR6247 |

1.28 |

12.22 |

32 |

17000 |

247 |

167 |

115 |

250 |

120 |

490 |

|

TBR6272 |

2.16 |

20.62 |

45 |

16000 |

272 |

182 |

125 |

260 |

130 |

520 |

|

TBR6300 |

2.9 |

27.69 |

52.9 |

14000 |

300 |

205 |

140 |

270 |

145 |

560 |

|

TBR6330 |

3.46 |

33 |

78 |

12000 |

330 |

217 |

155 |

290 |

160 |

610 |

|

TBR6360 |

4.13 |

39.44 |

101 |

10000 |

360 |

247 |

170 |

310 |

175 |

660 |

|

TBR8212 |

0.86 |

8.21 |

24.1 |

20000 |

212 |

130 |

90 |

230 |

95 |

420 |

|

TBR8233 |

1.28 |

12.22 |

32 |

18000 |

233 |

150 |

105 |

250 |

110 |

470 |

|

TBR8248 |

2.16 |

20.62 |

45 |

17000 |

248 |

167 |

115 |

250 |

120 |

490 |

|

TBR8274 |

2.9 |

27.69 |

52.9 |

16000 |

274 |

182 |

125 |

260 |

130 |

520 |

|

TBR8302 |

3.46 |

33 |

78 |

14000 |

302 |

205 |

140 |

270 |

145 |

560 |

|

TBR8333 |

4.13 |

39.44 |

101 |

12000 |

333 |

217 |

150 |

290 |

160 |

610 |

|

TBR8363 |

6.6 |

63 |

140 |

10000 |

363 |

247 |

165 |

310 |

175 |

660 |

|

TBR8396 |

8.5 |

81.11 |

197 |

9500 |

396 |

263 |

175 |

320 |

180 |

680 |

|

TBR8425 |

11 |

105 |

217 |

9000 |

425 |

268 |

190 |

390 |

195 |

780 |

|

TBR8457 |

14 |

133.7 |

320 |

8500 |

457 |

300 |

205 |

400 |

210 |

820 |

|

TBR8493 |

17 |

162.3 |

355 |

8000 |

493 |

336 |

220 |

410 |

220 |

850 |

|

TBR8525 |

21 |

200.5 |

390 |

7500 |

525 |

344 |

240 |

450 |

240 |

930 |

|

TBR8570 |

26 |

248.3 |

570 |

7000 |

570 |

387 |

260 |

460 |

260 |

980 |

|

TBR8610 |

34 |

324.7 |

730 |

6000 |

610 |

419 |

285 |

480 |

290 |

1060 |

|

TBR0365 |

8.5 |

63 |

140 |

10000 |

365 |

247 |

165 |

310 |

175 |

660 |

|

TBR0400 |

11 |

81.11 |

197 |

9500 |

400 |

263 |

175 |

320 |

180 |

680 |

|

TBR0430 |

13 |

105 |

217 |

9000 |

430 |

268 |

190 |

390 |

195 |

780 |

|

TBR0460 |

16 |

133.7 |

320 |

8500 |

460 |

300 |

205 |

400 |

210 |

820 |

|

TBR0496 |

20 |

162.3 |

355 |

8000 |

496 |

336 |

220 |

410 |

220 |

850 |

|

TBR0537 |

25 |

238.75 |

548 |

7500 |

537 |

344 |

240 |

450 |

240 |

930 |

|

TBR0580 |

35 |

334.25 |

770 |

7000 |

580 |

387 |

260 |

460 |

260 |

980 |

|

TBR0630 |

42 |

401.1 |

920 |

6000 |

630 |

419 |

285 |

480 |

290 |

1060 |

|

联轴器型号 |

拧紧力矩(Nm) |

总质量(Kg) |

扭转刚度KT(Nm/radxE+06) |

转动惯量(Kgm^2) |

中间段每米长 |

角向不对中 |

轴向不对中 |

||||

|

质量(Kg) |

扭转刚度ΔKT(Nm/radxE+06) |

转动惯量(Kgm^2) |

特大θmax(deg) |

角向刚度(Nm/radxE+03) |

特大(mm) |

轴向力(N) |

|||||

|

TBR6115 |

45 |

6.2 |

0.15 |

0.009 |

4.7 |

0.00389 |

0.00612 |

0.375 |

110.3 |

2 |

902 |

|

TBR6135 |

45 |

11.6 |

0.25 |

0.021 |

6.0 |

0.099 |

0.013 |

0.375 |

119.5 |

2.3 |

1056 |

|

TBR6152 |

45 |

14.3 |

0.32 |

0.034 |

6.9 |

0.158 |

0.021 |

0.375 |

155.7 |

2.4 |

1368 |

|

TBR6175 |

85 |

19.5 |

0.42 |

0.076 |

10.4 |

0.289 |

0.035 |

0.375 |

168.2 |

2.6 |

2100 |

|

TBR6196 |

160 |

27.2 |

0.75 |

0.132 |

11.8 |

0.455 |

0.047 |

0.375 |

205.3 |

2.8 |

2306 |

|

TBR6210 |

160 |

34.5 |

1.12 |

0.181 |

13.5 |

0.702 |

0.085 |

0.375 |

213.6 |

3.0 |

3256 |

|

TBR6231 |

160 |

47.5 |

1.94 |

0.28 |

15.1 |

0.836 |

0.129 |

0.375 |

401.9 |

3.1 |

3654 |

|

TBR6247 |

160 |

58.3 |

2.35 |

0.41 |

22.6 |

1.536 |

0.172 |

0.375 |

447.2 |

3.3 |

3946 |

|

TBR6272 |

280 |

68.5 |

2.95 |

0.65 |

26.5 |

2.03 |

0.216 |

0.375 |

535.2 |

3.5 |

4653 |

|

TBR6300 |

280 |

82.3 |

4.86 |

1.02 |

39.5 |

2.76 |

0.444 |

0.375 |

592.3 |

3.6 |

5621 |

|

TBR6330 |

340 |

126.5 |

7.12 |

1.62 |

47.3 |

5.422 |

0.522 |

0.375 |

667.2 |

3.8 |

7624 |

|

TBR6360 |

540 |

158.2 |

9.85 |

2.43 |

53.2 |

7.032 |

0.755 |

0.375 |

720.3 |

4 |

9678 |

|

TBR8212 |

160 |

35.2 |

1.75 |

0.192 |

13.5 |

0.702 |

0.085 |

0.25 |

704.5 |

2 |

1458 |

|

TBR8233 |

160 |

48.6 |

2.2 |

0.29 |

15.1 |

0.836 |

0.129 |

0.25 |

1130 |

2.2 |

3542 |

|

TBR8248 |

160 |

59.3 |

2.85 |

0.43 |

22.6 |

1.536 |

0.172 |

0.25 |

1469 |

2.4 |

4216 |

|

TBR8274 |

280 |

70.2 |

3.92 |

0.72 |

26.5 |

2.03 |

0.216 |

0.25 |

1635 |

2.6 |

4568 |

|

TBR8302 |

280 |

83.2 |

5.42 |

1.13 |

39.5 |

2.76 |

0.444 |

0.25 |

1989 |

2.8 |

6542 |

|

TBR8333 |

340 |

127.2 |

8.54 |

1.73 |

46.3 |

5.422 |

0.522 |

0.25 |

2653 |

3.0 |

9326 |

|

TBR8363 |

540 |

159.5 |

9.93 |

2.68 |

51.2 |

7.032 |

0.755 |

0.25 |

3456 |

3.3 |

12681 |

|

TBR8396 |

540 |

202.3 |

11.86 |

3.95 |

56.1 |

8.865 |

0.923 |

0.25 |

7864 |

3.4 |

13653 |

|

TBR8425 |

800 |

273.5 |

14.76 |

5.68 |

71.5 |

14.65 |

1.101 |

0.25 |

6859 |

3.6 |

15782 |

|

TBR8457 |

800 |

316.4 |

18.65 |

6.96 |

87.3 |

16.83 |

1.522 |

0.25 |

6971 |

3.8 |

16524 |

|

TBR8493 |

800 |

388.5 |

22.47 |

11.53 |

94.6 |

21.32 |

2.11 |

0.25 |

7865 |

4.0 |

18936 |

|

TBR8525 |

1200 |

472.5 |

25.87 |

15.72 |

105.3 |

25.66 |

2.56 |

0.25 |

8654 |

4.2 |

19856 |

|

TBR8570 |

1200 |

583.5 |

34.61 |

23.65 |

136 |

40.37 |

4.03 |

0.25 |

8475 |

4.6 |

20541 |

|

TBR8610 |

1800 |

667.4 |

44.56 |

31.11 |

147 |

50.8 |

5.07 |

0.25 |

9246 |

5 |

21456 |

|

TBR0365 |

540 |

160.5 |

12.13 |

2.88 |

51.2 |

7.032 |

0.755 |

0.165 |

7756 |

2.8 |

7652 |

|

TBR0400 |

540 |

203.5 |

15.24 |

4.15 |

56.1 |

8.865 |

0.923 |

0.165 |

12589 |

3.0 |

9862 |

|

TBR0430 |

800 |

275.4 |

16.65 |

5.98 |

71.5 |

14.65 |

1.101 |

0.165 |

21870 |

3.2 |

10635 |

|

TBR0460 |

800 |

318.4 |

23.15 |

7.31 |

87.3 |

16.83 |

1.522 |

0.165 |

24254 |

3.6 |

14963 |

|

TBR0496 |

800 |

390.5 |

26.45 |

12.21 |

94.6 |

21.32 |

2.11 |

0.165 |

26587 |

3.8 |

16985 |

|

TBR0537 |

1200 |

483.5 |

32.13 |

16.24 |

105.3 |

25.66 |

2.56 |

0.165 |

28954 |

4.0 |

18635 |

|

TBR0580 |

1200 |

590.1 |

38.26 |

24.35 |

136 |

40.37 |

4.03 |

0.165 |

33000 |

4.6 |

19886 |

|

TBR0630 |

1800 |

675.4 |

46.82 |

33.33 |

147 |

50.8 |

5.07 |

0.165 |

34251 |

5.2 |

23687 |

◆联轴器尺寸C、L、E、F是根据使用性能建议的标准值,可按用户要求设计。其它尺寸的L值,其扭转刚度、转动惯量等应另算;

◆径向不对中数值是角向不对中和中间节长度的函数,可近似按正切函数推倒;

◆扭转刚度是按表中结构尺寸得出的(已计入轴的配合段),当用户有特殊需要时可通过调整中间段长度E或有关尺寸而获得。若仅中间段长度E有变化,扭转刚度可由下式计算出:

式中: K-所需扭转刚度 -表上的扭转刚度 -中间段每米扭转刚度量 -尺寸E的变化值

◆对于有热膨胀的机组,安装时应考虑冷态预拉伸量,使挠性元件工作在较小的变形区间,提高使用寿命;

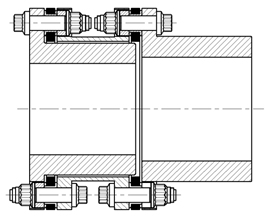

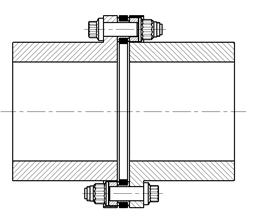

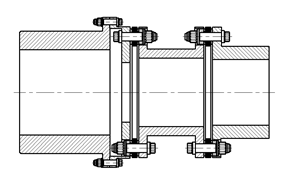

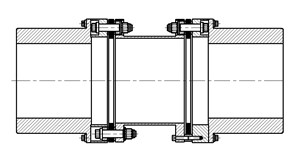

其它系列高速膜片联轴器

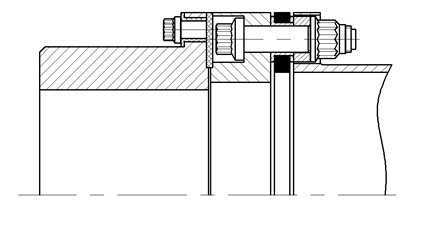

根据客户需要我们又将现有的型式进行了拓展来满足客户的需求,下面是结构简图: